Improve these to have accuracy colors for product packaging printing

Improve these to have accuracy colors for product packaging printing

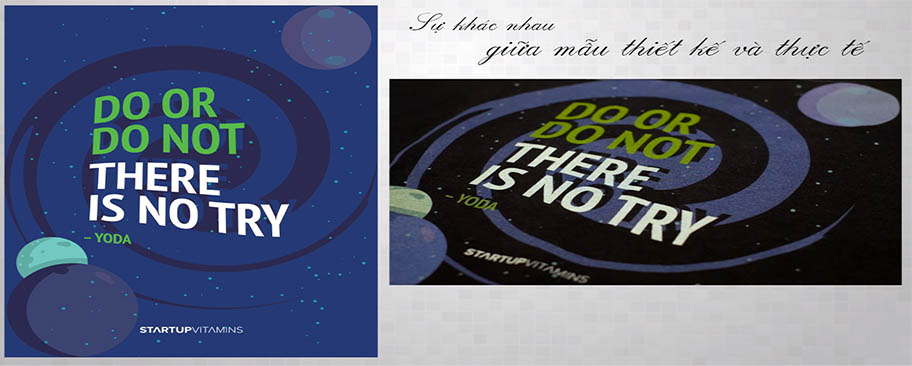

Color is one of the most important points that determine the success or failure of designs and printed packaging. However, during the printing process, colors may differ from the designs. So, how do you get a standard color publication? What causes the color difference in design and printing?

Perception of packaging printing colors depends on each person’s perception

Depending on the structure of the individual's eyes, the way each person sees colors (for the same product packaging) may vary. In particular, within the range of the blue bands, this is especially true. Besides, the color may also be affected if placed next to other colors. Colors can also change through reflection or as a visual illusion. Therefore, the perception of colors according to each person's perception is also different.

Each color has its own meaning and reflects the emotions of things

The perception of packaging printing colors may vary due to computer and printing technology

Depending on the computer and how the user sets the shades for contrast, the brightness of the colors that the computer screen displays varies colors. Besides, the color display on the computer also depends on the type of screen, the shades of packaging's color so that change. For example, LCD flat screens will show a greener color than other screens to increase the level of lightness for the user's eyes.>>> The power of CYMK color system in offset printing

In addition, in printing technology, the color of the publication also depends on the machine and printing technology used. Inkjet and laser printers which have modern technology is convenient do not have the color range that professional printers, or bright colors like on offset printing due to the mix different colors.

The color perception of packaging printing depends on the colorimetric tool

There are many publications on the market about the standard color system in the CMYK or Pantone color system. However, each packaging printing company has issued a separate standard color ink system and its own formula for standard color mixing according to that system..jpg)

CMYK color system is considered the standard color system in design and offset printing

Depending on the colorimetric tool, the resulting color will be standardized according to that tool. Therefore, the colors in the design change. In mass printing, the color between the design and the standard color adjustment print is relative. If the color requires absolute accuracy up to 99%, then you should print the mixed color and force the maker to mix the correct color and then print, this way is often used in screen printing or offset printing of zinc separately.

Colors may also vary between offset printer or digital printers, depending on device setup or calibration, so if you print your publication at different times or on different machines, tt may appear different colors.

Measures to minimize color difference in packaging printing

One of the problems leading to color misprinting is due to a confusion between the CMYK and RGB color systems. In print, you should use CMYK instead of RGB. It is the confusion between the two color systems CMYK and RGB (colors displayed on TV screens, computers...) leading to the situation that the printed output is deviated from the design.While the RGB color system is based on light emission (plus color) while the CMYK color system is based on the light absorption mechanism (minus color). Therefore, to minimize the color difference when printing, designers need to convert the RGB color system to the CMYK color system before printing.

>>> Offset or digital printing - Which is the better choice for paper packaging?

.jpg)

In addition, to avoid color difference, a common method that most printers use is the pattern printing method. The pattern printing method allows designers and print technicians to accurately assess the difference between the print and the original design before mass printing. This method allows the printer to confirm the standard color tone according to the designer's assessment so that the color HUE can be adjusted accordingly.

For offset printing, in order to have standard prints in the CMYK color system, many printing houses invest in a color test system, so that the printed output has the most accurate color. This standard color testing process can be costly, but will guarantee accurate color for mass print publications.

Getting accurate colors in printed product packaging is hard to achieve, but it is also one of the most important aspects of design. Therefore, designers and printers are always looking for ways to achieve the most accurate color between prints and designs. In order to achieve the best results, designers and printers need to be aware of the aspects that affect the variance in order to make the most appropriate adjustments, resulting in the best quality printouts.

Khang Thanh - The packaging manufacturer in Vietnam specializes in producing paper bags, carton box, carton offset, labels, hangtag, books, calendar, POSM and so on.

KHANG THANH - HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com