The power of the CMYK color system in offset printing

The power of the CMYK color system in offset printing

1. The concept of the CMYK color system in offset printing

2. Distinguish colorless and useful colors

3. Differentiate colors in offset printing

Colors in design and printing are extremely important factors that contribute to the quality of a harmonious and eye-catching design. No color deviation is a very important aspect. Therefore, choosing the printing color system and the color synthesis formulas in offset printing requires the printer to learn thoroughly, understand, and apply fluently.

Besides, printing companies and designers should also update more basic knowledge on how to synthesize colors in offset printing to better understand and support issues related to printing requirements. To understand these issues, first, let's explore the contents related to the CMYK color system, ways to distinguish colors, and differentiate colors from offset printing.

CMYK is a subtractive color system - the color system that the human eye sees thanks to the reflection of light and not the ability to self-emit light. CMYK is a color system in which colors are produced from a combination of four colors:

In particular, black (K) is the main color, key in the system of 4 colors (CMYK). The CMYK color system is the color system commonly used in offset printing, such as leaflets, books, newspapers, or magazines. In offset printing technology, the restoration of color of images is based on the principle of overlapping color separations, which correspond to 4 basic inks, including monochromatic colors in the CMYK color system. The color of images printed on paper that we perceive is a combination of subtraction and subtraction.

Instead of using 3 mixed C, M, and Y color ink or overlay printing to create black and gray (subtractive color theory), you can use auxiliary black ink or direct printing (completely replacing 3 ink C, M, and Y) to minimize costs.

>>> The power of the CMYK color system in offset printing

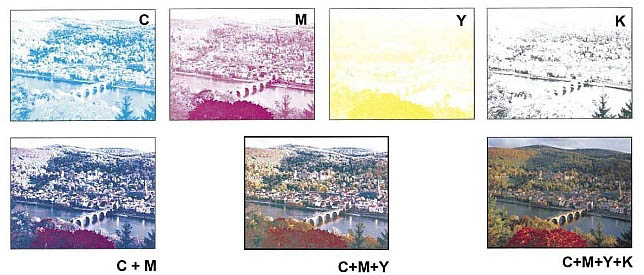

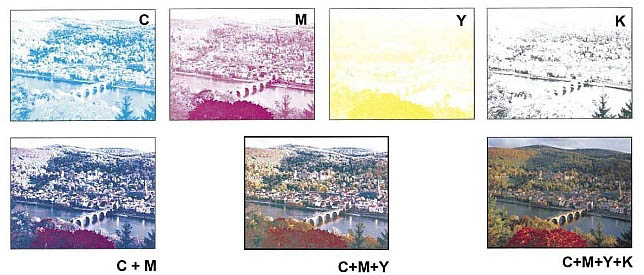

Colors C, M, Y, K when separated into separate color layers

To expand the image density range, black is only available in the darkest areas of the image to increase contrast and improve the sharpness of the images on the printed sheet. The method of color synthesis is still mainly based on the colors C, M, and Y.

As a result, it still costs a lot of ink, and at the same time, it is difficult to stabilize the gray balance when printing overlays, the shrinking color space is reduced, the sheets are dry, etc. Today, this method is no longer suitable for high-speed color printers, which are often used in offset printing.

This saves the cost of ink in offset printing technology, and because the thickness of the stack of ink in the dark area is reduced, the sheet dries faster and reduces the problem of smudged, sticky, or face miles.

The neutral gray value is the sum of 3 colors C, M, and Y, corresponding to the color with the lowest value (%), and is replaced by the equivalent color value K (%). The remaining color value is the sum of the component color values minus the neutral gray value. Thus, with the GCR algorithm, to restore the color of the image, it only needs to be black and one or at most two of the three colors, ink C, M, and Y. The GCR method clearly saves a lot of CMY ink compared to UCR in the offset printing method.

In terms of image quality and print quality, the GCR color grading method is applied when printing gray-balance overlays that are easy to achieve and stabilize with better ink transfer. The biggest disadvantage of GCR color grading is not high color saturation (reduction).

>>> 5 Basic steps in offset printing process

To create a neutral gray in the dark areas of an image due to insufficient black density, additional printing of C, M, and Y colors is added. Image quality and print quality (color saturation, image contrast) are 100% better than the GCR method in offset printing and still save more ink than the UCR method.

In order to have a clearer view of color synthesis in the offset printing method, packaging manufacturers and designers need to understand the principles and ways of synthesizing colors in the printing method to have a general view as well as the right application to produce quality, standard, sharp, and beautiful prints.

Khang Thanh is the leading printing company in Vietnam with a reputation for making every project look great. Our team of skilled and experienced professionals is equipped with the latest technology. This lets us offer full services that cover everything from design and prepress to printing and finishing.

>>> 8 Basic steps in manufacturing process in Vietnam packaging company

At Khang Thanh, we are proud that you can count on us for all of your printing needs in Vietnam. We believe in making strong connections with our clients based on quality, customer satisfaction, and creative approaches.

Contact us to support your brand with the right packaging.

KHANG THANH - HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com

2. Distinguish colorless and useful colors

3. Differentiate colors in offset printing

3.1 Synthesis of colors with complementary black

3.2 Synthesis of colors with UCR algorithm

3.3 Colorless synthesis with GCR algorithm

3.3 Colorless synthesis with complementary colors UCA

3.2 Synthesis of colors with UCR algorithm

3.3 Colorless synthesis with GCR algorithm

3.3 Colorless synthesis with complementary colors UCA

Colors in design and printing are extremely important factors that contribute to the quality of a harmonious and eye-catching design. No color deviation is a very important aspect. Therefore, choosing the printing color system and the color synthesis formulas in offset printing requires the printer to learn thoroughly, understand, and apply fluently.

Besides, printing companies and designers should also update more basic knowledge on how to synthesize colors in offset printing to better understand and support issues related to printing requirements. To understand these issues, first, let's explore the contents related to the CMYK color system, ways to distinguish colors, and differentiate colors from offset printing.

1. The concept of the CMYK color system in offset printing

CMYK and RGB are concepts of two color systems that we often encounter in design. However, in printing, people often use the CMYK color system. So what is the CMYK color system, and why is it often used in offset printing?CMYK is a subtractive color system - the color system that the human eye sees thanks to the reflection of light and not the ability to self-emit light. CMYK is a color system in which colors are produced from a combination of four colors:

- C (Cyan = Blue)

- M (Magenta = Lotus color - dark pink)

- Y (Yellow)

- K (Black)

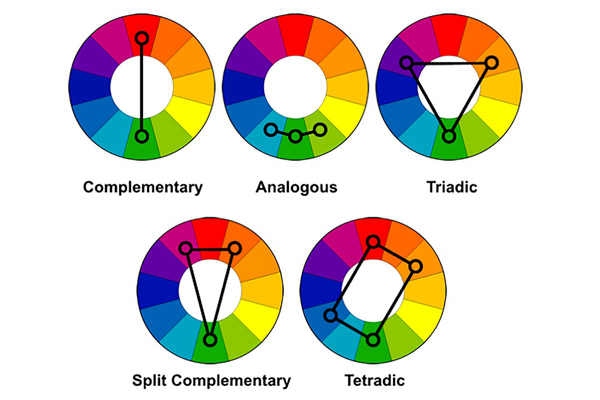

Differences between CMYK, RGB, and RYB color systems

In particular, black (K) is the main color, key in the system of 4 colors (CMYK). The CMYK color system is the color system commonly used in offset printing, such as leaflets, books, newspapers, or magazines. In offset printing technology, the restoration of color of images is based on the principle of overlapping color separations, which correspond to 4 basic inks, including monochromatic colors in the CMYK color system. The color of images printed on paper that we perceive is a combination of subtraction and subtraction.

Instead of using 3 mixed C, M, and Y color ink or overlay printing to create black and gray (subtractive color theory), you can use auxiliary black ink or direct printing (completely replacing 3 ink C, M, and Y) to minimize costs.

2. Distinguish colorless and useful colors in offset printing

- Colors C, M, and Y are called color ink, chromatic process inks

- The ink of K is called inkless, achromatic process ink.

- The method of synthesizing colors (called "chromatic composition - chromatic reproduction") is a method of synthesizing color to restore printed images formed mainly by C, M, and Y colors. K (Black) ink is only an adjunct (with or without) in the synthesis of colors in offset printing

- The method of synthesizing colorless colors (called: achromatic composition - achromatic reproduction) is the method of synthesizing the color of printed images in contrast to the method of synthesizing colors, taking K ink as the main method. Meanwhile, the ink colors C, M, and Y play auxiliary roles.

>>> The power of the CMYK color system in offset printing

Colors C, M, Y, K when separated into separate color layers

3. Differentiate colors in offset printing

3.1 Synthesis of colors with complementary black

To expand the image density range, black is only available in the darkest areas of the image to increase contrast and improve the sharpness of the images on the printed sheet. The method of color synthesis is still mainly based on the colors C, M, and Y.As a result, it still costs a lot of ink, and at the same time, it is difficult to stabilize the gray balance when printing overlays, the shrinking color space is reduced, the sheets are dry, etc. Today, this method is no longer suitable for high-speed color printers, which are often used in offset printing.

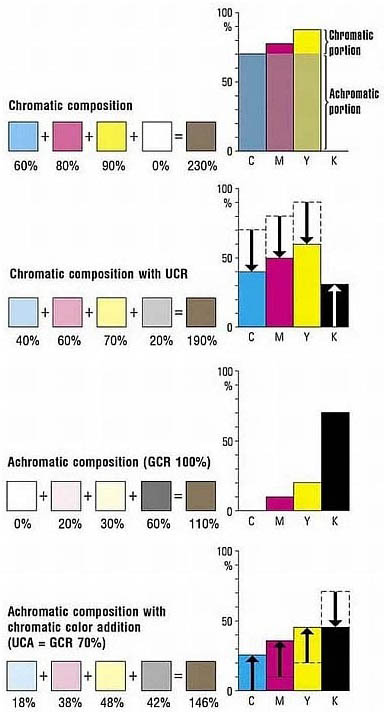

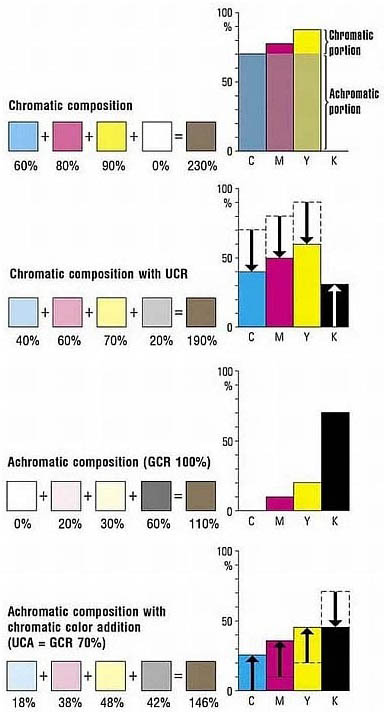

Differences between 4 color synthesis methods

3.2 Combining colors with UCR algorithm (Under Color Removal)

Black K (black) is created more in the dark areas of the image (black appears in the mid-tone area and increases gradually in the shadow area). The neutral gray shadows in the image (neutral image shadow), instead of synthesizing from C, M, and Y colors, are replaced with equivalent black tones.This saves the cost of ink in offset printing technology, and because the thickness of the stack of ink in the dark area is reduced, the sheet dries faster and reduces the problem of smudged, sticky, or face miles.

3.3 Colorless synthesis with GCR algorithm

This is a method for synthesizing colors to get black as the dominant color. Across the entire color space of the image, from the bright area to the dark area, the combined values of three colors C + M + Y will be separated into two different parts, including neutral gray value (achromatic value) and chromatic value.The neutral gray value is the sum of 3 colors C, M, and Y, corresponding to the color with the lowest value (%), and is replaced by the equivalent color value K (%). The remaining color value is the sum of the component color values minus the neutral gray value. Thus, with the GCR algorithm, to restore the color of the image, it only needs to be black and one or at most two of the three colors, ink C, M, and Y. The GCR method clearly saves a lot of CMY ink compared to UCR in the offset printing method.

In terms of image quality and print quality, the GCR color grading method is applied when printing gray-balance overlays that are easy to achieve and stabilize with better ink transfer. The biggest disadvantage of GCR color grading is not high color saturation (reduction).

>>> 5 Basic steps in offset printing process

Offset printing process with CMYK color system

3.4 Combining colorless with the complementary color

This is also called the method of synthesizing incomplete colors (GCR 50%, GCR 70%, GCR medium, and GCR heavy). With this method, the black is created to partially replace the neutral gray value and not completely replace it (UCA stands for Under Color Addition).To create a neutral gray in the dark areas of an image due to insufficient black density, additional printing of C, M, and Y colors is added. Image quality and print quality (color saturation, image contrast) are 100% better than the GCR method in offset printing and still save more ink than the UCR method.

In order to have a clearer view of color synthesis in the offset printing method, packaging manufacturers and designers need to understand the principles and ways of synthesizing colors in the printing method to have a general view as well as the right application to produce quality, standard, sharp, and beautiful prints.

The printing company in Vietnam

Khang Thanh is the leading printing company in Vietnam with a reputation for making every project look great. Our team of skilled and experienced professionals is equipped with the latest technology. This lets us offer full services that cover everything from design and prepress to printing and finishing.>>> 8 Basic steps in manufacturing process in Vietnam packaging company

At Khang Thanh, we are proud that you can count on us for all of your printing needs in Vietnam. We believe in making strong connections with our clients based on quality, customer satisfaction, and creative approaches.

Contact us to support your brand with the right packaging.

KHANG THANH - HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com