What to consider when choosing a book manufacturing company?

What to consider when choosing a book manufacturing company?

An effective and best book printing plan is the result of good quality and reasonable price. To do so, you need to take notes quickly with the following tips when choosing a book manufacturing company.

There is an undeniable fact that color ink will make the book more interesting and engaging. However, in book printing, you do not need to pay attention to this because the black and white of a book page is enough for readers to understand what you want to say through the words (for story books, novels).

This is in the case of a limited budget and, of course, no mention of scientific, design, or cooking publications that focus on color. Black ink pages and colored cardboard pages are common today that you can find in most books in bookstores.

Basically, if the book contains mostly text, the pages should be printed in black ink to save a lot.

>>> Offset printing or digital printing for paper packaging?

.jpg)

The weight of a book is also weighed and converted into money. However, this does not mean that you have to choose the thinnest paper possible for a low price. For a book with the sole purpose of reading words and a few images, a medium-sized paper is usually sufficient.

Currently, there are many different types of paper to ensure this factor. If using a lighter type of paper does not affect the look and the images you have in your book. That might be a better option. Not to mention, a lighter book will help you reduce the cost of shipping and distributing to official release points.

>>> Printing proof - A primary step for quality product packaging

.jpg)

.jpg)

You probably do not know that any book that produces cardboard can be made in paperback and vice versa. However, it is important that their cost is the point that you must consider carefully.

This is the point where paperback is commonly used when it is much cheaper. Because a paperback requires fewer manufacturing steps than cardboard. In addition, the paperback is just as nice as the cardboard. Paperback books also have faster production times and wider availability.

When it comes to booking manufacturing, we need to set a plan to avoid unnecessary consequences in this case. If a product is placed too high on it, the packaging company can get a much higher price than in any way.

>>> 5 Basic steps in offset printing process

.jpg)

Therefore, when planning to print books, do it immediately. Start researching and quickly contacting the production unit so they can help you prepare in time. This just ensures a beautiful product, saving time, and costs and minimizing errors that can occur during printing..

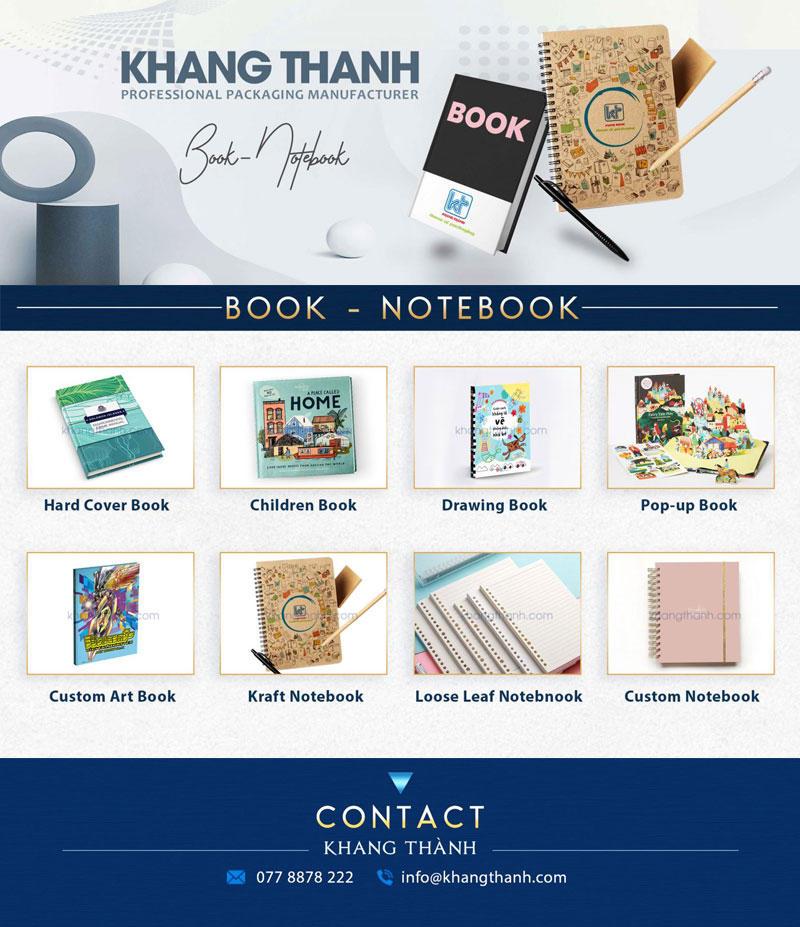

KHANG THANH - HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com

Black ink is cost-saving than color ink

There is an undeniable fact that color ink will make the book more interesting and engaging. However, in book printing, you do not need to pay attention to this because the black and white of a book page is enough for readers to understand what you want to say through the words (for story books, novels).This is in the case of a limited budget and, of course, no mention of scientific, design, or cooking publications that focus on color. Black ink pages and colored cardboard pages are common today that you can find in most books in bookstores.

Basically, if the book contains mostly text, the pages should be printed in black ink to save a lot.

>>> Offset printing or digital printing for paper packaging?

.jpg)

Page weight determines the pricing of book manufacturing

The weight of a book is also weighed and converted into money. However, this does not mean that you have to choose the thinnest paper possible for a low price. For a book with the sole purpose of reading words and a few images, a medium-sized paper is usually sufficient.Currently, there are many different types of paper to ensure this factor. If using a lighter type of paper does not affect the look and the images you have in your book. That might be a better option. Not to mention, a lighter book will help you reduce the cost of shipping and distributing to official release points.

>>> Printing proof - A primary step for quality product packaging

.jpg)

.jpg)

Consider choosing a paperback instead of a hard cover

You probably do not know that any book that produces cardboard can be made in paperback and vice versa. However, it is important that their cost is the point that you must consider carefully.This is the point where paperback is commonly used when it is much cheaper. Because a paperback requires fewer manufacturing steps than cardboard. In addition, the paperback is just as nice as the cardboard. Paperback books also have faster production times and wider availability.

When it comes to booking manufacturing, we need to set a plan to avoid unnecessary consequences in this case. If a product is placed too high on it, the packaging company can get a much higher price than in any way.

>>> 5 Basic steps in offset printing process

.jpg)

Therefore, when planning to print books, do it immediately. Start researching and quickly contacting the production unit so they can help you prepare in time. This just ensures a beautiful product, saving time, and costs and minimizing errors that can occur during printing..

KHANG THANH - HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com