How to produce secondary pharmaceutical packaging

How to produce secondary pharmaceutical packaging

Besides relevant and firm structures, secondary pharmaceutical packaging needs to meet specific standards to ensure consumer safety. The followings are what to know when manufacturing packaging of medicines, particularly secondary pharmaceutical packaging.

Depending on the contact level with the medicines, pharmaceutical packaging can be divided into two types:

Even though the secondary packaging does not come into direct contact with the product, the paper box also needs to ensure the safety of paper materials and production processes. Some commonly used paper box designs include tuck lids, locking lids, or serrated lids.

The main advantages of paper containers include:

>>> Paper box and what you do not know

Medicines directly affect consumers' health; hence, consumers always carefully research the information on the packaging before buying pharmaceutical products.

Therefore, when producing medicine paper boxes, the following basic information is required:

Paper box helps consumers to easily identify the brand and evaluate the quality and authenticity of the product.

>>> Paper boxes packaging - The face of every brand

Paper box helps minimize the external factors that impact the state of the medication such as light, temperature, humidity, and impact. Therefore, when manufacturing secondary pharmaceutical packaging, attention should be paid to the selection of materials.

Common types of paper boxes such as Duplex, Couche, Ford, and Ivory can combine G, F, E, B... flute to increase the rigidity of the paper box when stacking and transporting the medication.

Paper box, medicine paper bag combined with some outside processing to ensure the aesthetics and professionalism for the product such as glossy/matte lamination, UV/varnish coating, and also to increase the degree durable for the paper layer.

The characteristic of pharmaceutical products is that it is easily affected by external factors. So for the convenience of consumer use, packaging specifications should ensure easy opening and closing. Paper boxes need to ensure a closed box design, and withstand the impact of multi times of opening and closing.

>>> 6 Types of the most popular printing paper for packaging

As mentioned above, pharmaceutical products are products that directly affect the health of consumers. Therefore, in any stage of the production of pharmaceuticals, there is careful control of the competent authorities, including secondary packaging such as paper boxes.

When manufacturing packaging for pharmaceuticals, attention should be paid to the information printed on the packaging to facilitate the control of the authorities, specified in the decision on the production of packaging for pharmaceuticals. This information is usually the product barcode, the main ingredient of the product, expiry date, manufacturing date, and business information with the full tax code.

If you are not familiar with these regulations, it is best to choose a reputable packaging company for the most accurate advice.

Khang Thanh – The packaging company in Vietnam specializes in producing gift bags, rigid boxes, POSM, and so on. Contact us to support your brand with the right packaging:

KHANG THANH - HOUSE OF PACKAGING

Tel: (+84) 77 8878 222

Email: info@khangthanh.com

What are primary and secondary pharmaceutical packagings?

Depending on the contact level with the medicines, pharmaceutical packaging can be divided into two types:

- Primary packaging: The packaging in direct contact with medicines such as blister packs, tear blisters, bottles, and jars. This type is strictly controlled to meet safety standards in healthcare.

- Secondary packaging: The packaging is not in direct contact with the medicines, which are paper boxes, and bottles. Secondary pharmaceutical packaging is mainly for information printing, easy storage, and transportation.

Even though the secondary packaging does not come into direct contact with the product, the paper box also needs to ensure the safety of paper materials and production processes. Some commonly used paper box designs include tuck lids, locking lids, or serrated lids.

Advantages of the paper boxes as secondary pharmaceutical packaging

The main advantages of paper containers include:

- Protect medicines from external agents such as temperature, humidity, light, and impact during transportation;

- Provide information on the packaging for consumers to easily identify and use the medicines properly;

- Promote product brands;

- Easy to transport, increasing the authenticity and reliability of the product.

>>> Paper box and what you do not know

Paper secondary pharmaceutical packaging needs to include clear information

Medicines directly affect consumers' health; hence, consumers always carefully research the information on the packaging before buying pharmaceutical products.Therefore, when producing medicine paper boxes, the following basic information is required:

- Paper material

- Content or concentration (if any)

- Standard of the material

- Net weight or volume

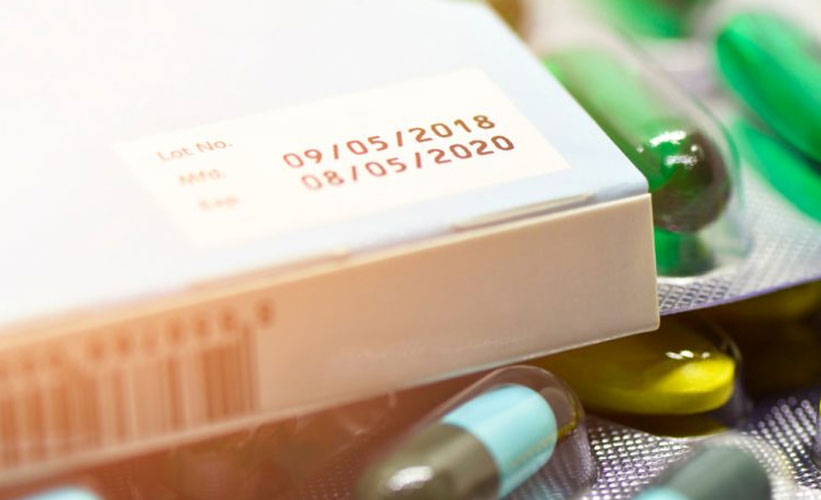

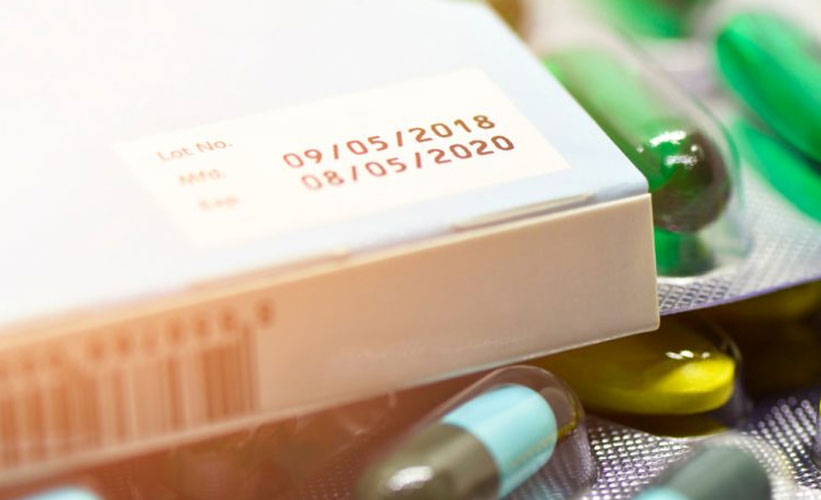

- Lot number, date of manufacture

- Expiry date, storage conditions

- Registration number (if any)

- Name and address of the manufacturer, origin of the medicine

- Name and address of the importer (for imported raw materials)

Paper box helps consumers to easily identify the brand and evaluate the quality and authenticity of the product.

>>> Paper boxes packaging - The face of every brand

Chose materials for secondary pharmaceutical packaging

Paper box helps minimize the external factors that impact the state of the medication such as light, temperature, humidity, and impact. Therefore, when manufacturing secondary pharmaceutical packaging, attention should be paid to the selection of materials.Common types of paper boxes such as Duplex, Couche, Ford, and Ivory can combine G, F, E, B... flute to increase the rigidity of the paper box when stacking and transporting the medication.

Paper box, medicine paper bag combined with some outside processing to ensure the aesthetics and professionalism for the product such as glossy/matte lamination, UV/varnish coating, and also to increase the degree durable for the paper layer.

The characteristic of pharmaceutical products is that it is easily affected by external factors. So for the convenience of consumer use, packaging specifications should ensure easy opening and closing. Paper boxes need to ensure a closed box design, and withstand the impact of multi times of opening and closing.

>>> 6 Types of the most popular printing paper for packaging

Strictly complying with the regulations in manufacturing secondary packaging

As mentioned above, pharmaceutical products are products that directly affect the health of consumers. Therefore, in any stage of the production of pharmaceuticals, there is careful control of the competent authorities, including secondary packaging such as paper boxes.When manufacturing packaging for pharmaceuticals, attention should be paid to the information printed on the packaging to facilitate the control of the authorities, specified in the decision on the production of packaging for pharmaceuticals. This information is usually the product barcode, the main ingredient of the product, expiry date, manufacturing date, and business information with the full tax code.

If you are not familiar with these regulations, it is best to choose a reputable packaging company for the most accurate advice.

Khang Thanh – The packaging company in Vietnam specializes in producing gift bags, rigid boxes, POSM, and so on. Contact us to support your brand with the right packaging:

KHANG THANH - HOUSE OF PACKAGING

Tel: (+84) 77 8878 222

Email: info@khangthanh.com