How to print logos on rigid boxes for a premium look

How to print logos on rigid boxes for a premium look

Without the right printing technique, even luxury rigid boxes can fall short in conveying brand value. Therefore, the skillful use of premium printing effects will give the custom rigid box the luxurious finish it deserves.

So how to ensure the logo enhances the perceived value of brand packaging? Choosing the right printing effect is key. In this article, Khang Thanh will suggest 04 popular techniques for logo effects on rigid boxes.

So how to ensure the logo enhances the perceived value of brand packaging? Choosing the right printing effect is key. In this article, Khang Thanh will suggest 04 popular techniques for logo effects on rigid boxes.

Which effect is the best choice for luxury rigid box?

Why choose effects for printing rigid boxes?

Frequently asked questions

Why choose effects for printing rigid boxes?

Frequently asked questions

4 printing effect logos on rigid boxes for a premium look

The brand logo printed on the rigid box is not only for identification but also to convey exclusivity and luxury. Therefore, choosing the right printing technique will accurately represent the brand value that the brand wants to convey.

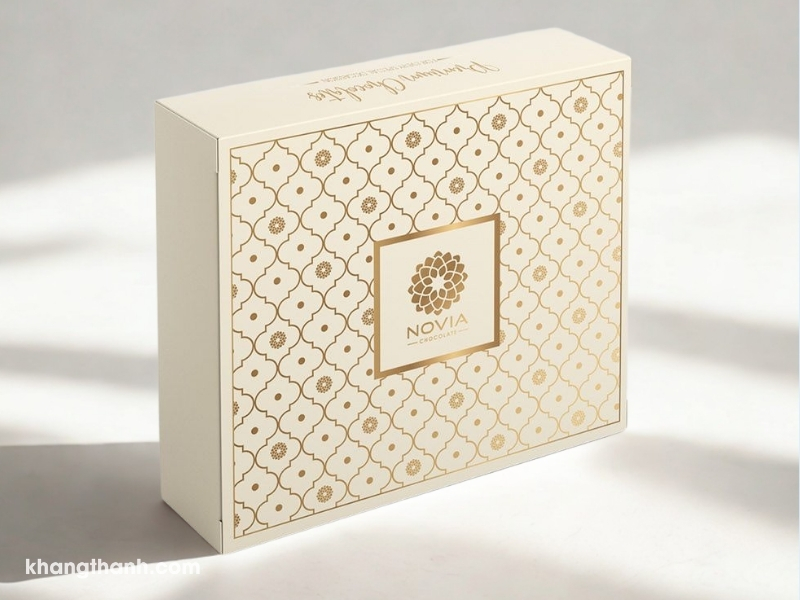

Hot foil stamping

Hot foil stamping involves applying a metallic or pigmented foil to the surface of the custom rigid box using heat and pressure. It creates a reflective, shiny finish that instantly conveys a luxury appeal. Common choices include gold, silver, copper, rose gold, and holographic films.

This technique is widely used on luxury rigid boxes, especially for cosmetics, jewelry, electronics, or premium gift sets. Because the effect has visually striking, catches the light beautifully, and looks clean against dark backgrounds.

Pros:

This technique is widely used on luxury rigid boxes, especially for cosmetics, jewelry, electronics, or premium gift sets. Because the effect has visually striking, catches the light beautifully, and looks clean against dark backgrounds.

Pros:

- High-end, luxurious appearance

- Wide range of metallic and pigment colors

- Durable and resistant to fading

Cons:

- Requires custom dies (additional setup cost)

- Less suitable for intricate or thin designs

Embossing for rigid boxes

Embossing is a tactile printing method that raises the logo above the surface of the rigid box, creating a three-dimensional effect. Unlike foil stamping, embossing does not require logo color while still maintaining a subtle look.

The method will often be used for minimalist packaging, traditional or high-end craft brands that want to convey content without being ostentatious.

Pros:

The method will often be used for minimalist packaging, traditional or high-end craft brands that want to convey content without being ostentatious.

Pros:

- Adds a subtle yet elegant tactile dimension

- Can be used with or without ink or foil

- Eco-friendly option if color is avoided

Cons:

- Requires a custom metal die

- Thinner paper wraps may wrinkle or warp

- Limited detail on very small text or thin lines

Debossing for custom rigid box

Debossing is the reverse of embossing with the logo is pressed into the surface and create an indented design. While embossing calls attention to the logo with raised prominence, debossing creates a quiet sense of depth and elegance.

Pros:

Pros:

- Subtle and refined finish

- Enhances soft-touch or matte lamination

- Pairs well with other effects for a layered look

Cons:

- May be hard to notice on busy or patterned designs

- Not ideal for dark boxes unless paired with foil

Spot UV coating

Spot UV coating applies a high-gloss layer to specific areas of the logo by using ultraviolet light to cure the coating instantly. The result is a sleek, glossy effect that contrasts against a matte surface.

Unlike embossing or foil printing, spot UV coating does not add texture but only gloss. This makes the effect cost-effective and suitable for small quantities. Besides, the effect also more environmentally friendly than foil printing because it uses less material.

Spot UV printing of logos is often used on custom rigid boxes for brands that want to be minimalist, cost-effective, and still need neat, beautiful packaging. For example, electronics, cosmetics brands, or jewelry boxes with a single UV on brand name.

Unlike embossing or foil printing, spot UV coating does not add texture but only gloss. This makes the effect cost-effective and suitable for small quantities. Besides, the effect also more environmentally friendly than foil printing because it uses less material.

Spot UV printing of logos is often used on custom rigid boxes for brands that want to be minimalist, cost-effective, and still need neat, beautiful packaging. For example, electronics, cosmetics brands, or jewelry boxes with a single UV on brand name.

Which effect is the best and cheapest?

There is no one-size-fits-all solution, as each technique used on rigid boxes offers different advantages such as durability, set-up costs, final effects, and color combinations.

If a brand needs to print a logo with depth while saving costs, embossing and debossing are recommended. However, the effect will involve creating a mold, which will only save costs for rigid box orders of 5,000 to 10,000 pieces.

In addition, a more economical and worthy option is spot UV. Because, the logo printing technique will create contrast and gloss without the need for a mold. In addition, production is also faster, suitable for large orders of rigid boxes.

To optimize costs, brands can consider using effects selectively. For example, applying foil only to the logo and not the entire box. Or combining a matte finish with spot UV creates a premium feel without the need for additional tools.

If a brand needs to print a logo with depth while saving costs, embossing and debossing are recommended. However, the effect will involve creating a mold, which will only save costs for rigid box orders of 5,000 to 10,000 pieces.

In addition, a more economical and worthy option is spot UV. Because, the logo printing technique will create contrast and gloss without the need for a mold. In addition, production is also faster, suitable for large orders of rigid boxes.

To optimize costs, brands can consider using effects selectively. For example, applying foil only to the logo and not the entire box. Or combining a matte finish with spot UV creates a premium feel without the need for additional tools.

Why choose effects for printing rigid boxes?

Beyond decoration, logo printing effects play a critical role in perception, branding, and consumer experience. Here's why brands always prioritize printing effects on the surface of rigid boxes.

Enhance the perceived value of the product

A logo that sparkles, stands out or is subtly sunken on the surface of a hard box shows that the product inside is also invested in carefully. This advantage will help customers quickly position the premium value in the subconscious of consumers through the packaging.

Strengthening brand identity

Each technique speaks a different visual language. Foil stamping exudes luxury, embossing suggests artisanal care, and spot UV adds modernity. The right effect reinforces how your brand is remembered.

Making packaging socially appealing

Unboxing has become a shareable experience. A premium rigid box with a prominent logo effect will photograph beautifully and inspire content creation. Therefore, a beautiful rigid box will help your brand become more widely known.

Luxury rigid boxes help brands stand out in retail

In competitive retail environments, especially in cosmetics or tech, a reflective or textured logo grabs attention and makes the product more noticeable from a distance.

FAQ about printing effects on luxury rigid boxes

- What’s the most cost-effective logo printing technique?

Spot UV is generally the most affordable option. It requires no dies or molds and works well on matte-laminated surfaces to create a subtle, elegant finish.

- Can brands use foil and embossing at the same time?

Yes. Many brands combine foil stamping and embossing to create a raised, shiny logo that is both visual and tactile. However, this combination increases die costs and should be used strategically.

- What is the typical MOQ for rigid boxes with special logo effects?

Minimum orders vary by manufacturer but typically start at 500 to 1,000 units for foil stamping or embossing due to the cost of custom dies. Spot UV may allow lower volumes.

- Can I print logos on recycled paper rigid boxes?

Yes, but the surface texture of the recycled paper may affect the sharpness and clarity of the print. For premium rigid box, Ivory, Duplex, Couche paper is recommended for the paper base to best show the effect.

The benefits of carefully selected and printed brand logos on rigid boxes are more than you think. With smart choices, brands can create unique and satisfying premium rigid box experiences for their customers. So don’t overlook the power of thoughtful printing finishes.

Need help choosing the right finish for your logo? Work with a trusted custom rigid box manufacturer who understands printing techniques and can guide to find the best solution for brands and budget.

KHANG THANH - HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com

Take a look at premium effects of rigid box made by Khang Thanh.