How to pick the right rigid box size for your product

How to pick the right rigid box size for your product

Selecting the right rigid box size isn’t just about aesthetics, it’s a business-critical decision. A rigid box that’s too big wastes materials, increases shipping costs, and risks product damage during transit. On the other hand, the packaging that’s too tight can damage your item or make it difficult for customers to unpack.

This guide explores the common mistakes in rigid box dimensions, and offers a step-by-step solution to help brands select the ideal box size for products.

This guide explores the common mistakes in rigid box dimensions, and offers a step-by-step solution to help brands select the ideal box size for products.

Common mistakes when choosing rigid box sizes

1. Estimating instead of measuring

Many brands make the mistake of estimating product dimensions instead of using precise measurements. Even small discrepancies of a few millimeters can result in a poor fit.

In addition, measuring the exact size helps brands understand the rigid box dimensions to work with packaging manufacturer. Because when calculating the unit price of a rigid box, size will account for 40% of the price decision.

In addition, measuring the exact size helps brands understand the rigid box dimensions to work with packaging manufacturer. Because when calculating the unit price of a rigid box, size will account for 40% of the price decision.

2. Ignoring product accessories

Focusing solely on the main product without accounting for add-ons leads to boxes that don’t accommodate the entire package. The accessories can be manuals, handle, insert tray…

3. Overlooking protective inserts

Rigid boxes often include foam, EVA trays, or molded pulp inserts. If not factored into the dimensions, these elements can cause fitting issues such as lack of space or the size of luxury rigid box being too small for the inserts.

4. Misalignment with logistics

Choosing the wrong rigid box dimensions may also increase shipping costs due to dimensional weight pricing or cause issues with stacking and storage in warehouses.

5. Wrong thinking when one size can fit all

Different products need different packaging solutions. A luxury rigid box for perfume requires different specs than a premium rigid box for wine or electronics.

In order to save costs, the brand uses the structural drawing of the cosmetic rigid box size for the wine box, which is incorrect. Because there will happen a case premium rigid box for wine will no longer meet the protection function properly. The packaging may be too big or too small for the bottle. This design mistake will not protect the product well, and making the overall packaging unbalanced.

In order to save costs, the brand uses the structural drawing of the cosmetic rigid box size for the wine box, which is incorrect. Because there will happen a case premium rigid box for wine will no longer meet the protection function properly. The packaging may be too big or too small for the bottle. This design mistake will not protect the product well, and making the overall packaging unbalanced.

Step-by-step guide to finding the right rigid box size

Choosing the right rigid box size can save businesses money on sample costs, production, and storage fees. Khang Thanh suggests 6 detailed ways for brands to measure and pick the right rigid box dimension.

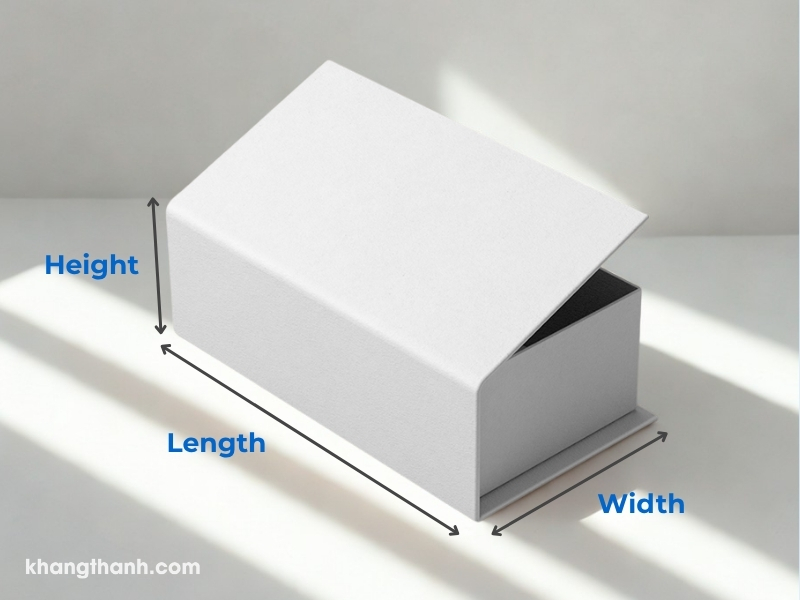

Step 1: Understand basic rigid box dimensions

Rigid boxes typically follow the standard packaging dimension format: Length (L) x Width (W) x Height (H)

- Length – the longest side of the product (left to right)

- Width – the shorter side (front to back)

- Height – the depth of the product (bottom to top)

Understanding basic dimensions will help brands communicate more easily with rigid box printers.

Step 2: Measure product precisely

Use a digital caliper or measuring tape to get precise measurements of your product. Besides, brands should design a detailed excel sheet and consider the following factors:

- The product, for example a wine bottle, jewelry, foundation or perfume bottle, etc.

- The height of the lid or handle (if any)

- Take into account the fragility of the product. Because more fragile products need more protective space

- How many millimeters thick is the rigid box needed

Step 3: Add buffer space

Next, when having the exact product size, add extra space for:

- Cushioning (foam, cardboard, EVA tray)

- Handling space (for easier unpacking)

- Tolerances (±2–3 mm to avoid tight fits)

Khang Thanh suggests a general rule of thumb when finalising the dimensions of a rigid box is should add 5–10 mm on each side unless using tight-fitting tray inserts.

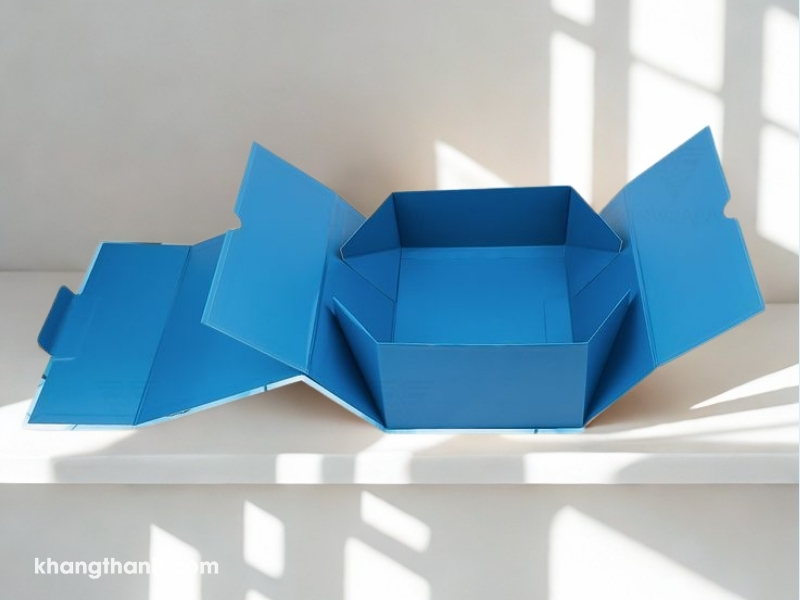

Step 4: Choose the right rigid box structure

Rigid boxes come in several structural styles that affect internal usable space. Choosing the right structure will ensure the harmony, ease of viewing and sturdiness of the premium rigid box.

5 most popular and easy to order luxury rigid box models for reference:

5 most popular and easy to order luxury rigid box models for reference:

- Custom shoulder neck boxes: Ideal for high-end cosmetics or perfumes. Because the neck of the box increases the space inside for better protection.

- Magnetic closure luxury boxes: Suitable for tech items, clothing and gifts because the closing mechanism can optimize the height of the rigid box.

- Drawer rigid boxes: Suitable for small accessories, watches or jewelry

- Lid and base box: Should be used to store spirits because the size will be suitable as a rectangular box that fits the length of a wine bottle...

Step 5: Select custom fit or standard sizes

An important step is to choose a custom rigid box or order a standard size box.

Khang Thanh recommends that brands should choose custom premium boxes for high-end items, seasonal gifts, or boxes that require a unique unboxing experience. On the contrary, choose a standard size rigid box for bulk shipments or B2B, B2C, and retail.

Option 1: Custom rigid box

Pros:

Khang Thanh recommends that brands should choose custom premium boxes for high-end items, seasonal gifts, or boxes that require a unique unboxing experience. On the contrary, choose a standard size rigid box for bulk shipments or B2B, B2C, and retail.

Option 1: Custom rigid box

Pros:

- Perfectly matches with product shape

- Enhances branding with structural uniqueness

- Optimizes logistics

Cons:

- Higher setup cost

- Longer lead time

Option 2: Premium rigid boxes with standard sizes

Pros:

- Faster production

- Cost-effective

- Good for generic SKUs

Cons:

- May require more fillers

- Less “luxury” impression

Step 6: Evaluate packaging for shipping & storage

Once the rigid box size is established, consider how the packaging will interact with distribution and retail needs. This step is important because the carefully calculated rigid box dimensions should not impact warehousing and shipping costs.

- Shipping: Ensure luxury rigid box fits the shipping carton and insert cardboard padding if necessary.

- Stacking: Boxes should be uniform in shape to maximize stacking.

- Shelf display: Ensure the size is appropriate for the shelf the brand is targeting. For example, use a large and double-opening rigid box for a central display. In contrast, customize a small box for a small display in a glass cabinet.

Tips to custom the right box size

Besides the 6 steps above, brands also need to understand the 2 tips below to print premium rigid boxes smoothly at a good price.

1. Making real sample before mass production

In fact, customers often skip this step because they are afraid of the cost. However, the sample box production step is very necessary because it is the main basis for brands to work and negotiate prices with packaging units. In addition, having the size of the rigid box before mass production will minimize the risk of cost and error.

Therefore, customers should always ask for a physical sample box to confirm the following requirements:

Therefore, customers should always ask for a physical sample box to confirm the following requirements:

- Actual fit of the product inside

- Function of the lid, drawer or magnetic lock

- Accuracy of the insert

- Visual appeal

2. Get expert help from a packaging manufacturer

Customers apply the above 6 steps but still do not get the desired rigid box size. Then cooperate with a reliable rigid box manufacturer to get a comprehensive solution.

Paper packaging printing company not only ensures the size, structural integrity, but also suggests suitable customized rigid box models.

Especially for brands targeting the global premium rigid box market, having the support of the right manufacturer is very important. Because customers can optimize costs and time effectively when having a packaging manufacturer to do the research, measurement, quotation and delivery.

Paper packaging printing company not only ensures the size, structural integrity, but also suggests suitable customized rigid box models.

Especially for brands targeting the global premium rigid box market, having the support of the right manufacturer is very important. Because customers can optimize costs and time effectively when having a packaging manufacturer to do the research, measurement, quotation and delivery.

Choosing the right rigid box size can be the difference between an ordinary and extraordinary unboxing experience. With this guide, customers can avoid costly dimensioning mistakes and optimize packaging for performance, aesthetics, and sustainability.

Need help choosing the perfect premium rigid box size for product? Talk to Khang Thanh packaging experts and get a free consultation on rigid box size, structure and performance.

KHANG THANH - HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com