Converting RGB to CMYK color in offset printing 2025

Converting RGB to CMYK color in offset printing 2025

1. Concept of CMYK color system in offset printing

2. Basic principles of CMYK color system

3. Distinguishing CMYK and RGB

4. How to convert RGB to CMYK

5. Notes when converting

6. Offset printing packaging at Khang Thanh

2. Basic principles of CMYK color system

3. Distinguishing CMYK and RGB

4. How to convert RGB to CMYK

5. Notes when converting

6. Offset printing packaging at Khang Thanh

Color is the most complex element in printed product packaging. The phenomenon of color deviations when printing is common, so optimizing the CMYK color system to create CMYK color separators suitable for each printing method is considered. Colors of offset printing cartons must be true, vivid, create specific senses for users.

According to the study, up to 85% of consumers' buying decisions are influenced by color. Therefore, the optimization of printing colors is considered as a vital factor affecting the product. So what is the CMYK color system and how does this color system apply to the production of offset printing carton packaging?

The concept of CMYK color system in paper packaging

The CMYK system is a color system in which colors are produced from a combination of the following 4 colors:

- Color C: Blue (Cyan)

- Color M: Lotus color - dark pink (Magenta)

- Color Y: Yellow (Yellow)

- Color K: Black (Black)

This is a subtractive color system because these are the colors we see by the reflection of the light and not the ability to glow. For example, when we see a red object, this object absorbs the wavelength of another color and reflects the red wavelength to the eye of the viewer. CMYK color system is a color system often used in offset printing for products such as cartons, POSM publications, and namecards.

>>> 5 basic steps in offset printing process

Basic principles of CMYK color system in paper packaging

The working principle of CMYK is on the basis of absorbing light. The color we see is from the part of light that is not absorbed. In CMYK dark pink plus yellow will give red, lotus plus blue gives blue, blue combined with yellow produces green and a combination of blue, lotus and yellow colors produce black.Because the black produced by blending the original colors is not really the same as the true black ink or the black of pure black - the black color of the object that absorbs all light. Printing on a four-color basis must use black ink in addition to the original colors, excluding yellow, lotus and blue colors. This is also the principle of basic coloring to master in offset printing.

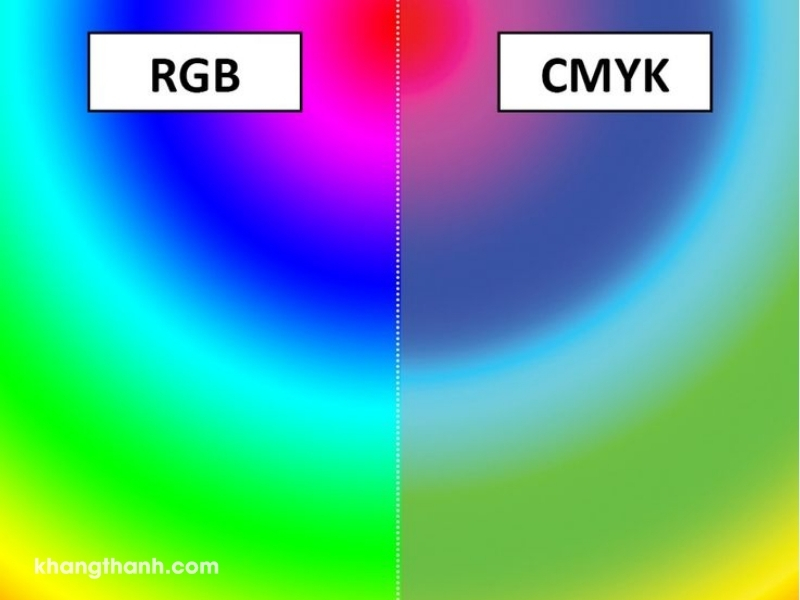

Differentiate CMYK and RGB in paper packaging solution

The use of four-color printing technology results in high-end offset carton packaging printing results with a high level of contrast. However, the color of the image that people see on a computer screen usually has a slight difference with the original color when printed because the CMYK and RGB color models (used in computers) have the different color tones.While the RGB color model is a model that operates on the basis of light emission (complementary colors), the CMYK model works by the mechanism of light absorption (color exclusion). If CMYK is a designer who can start from a blank sheet of paper and then add other colors, then RGB works the opposite.

>>> The power of the CMYK color system in offset printing

How to convert RGB to CMYK in paper packaging solution

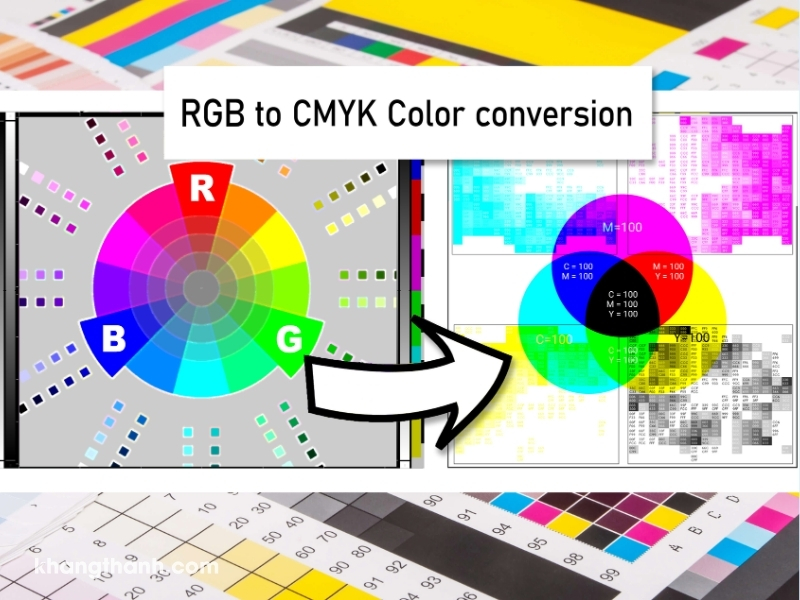

The principle of converting from RGB to CMYK is to start from converting from RGB to CMY, then converting CMY to CMYK.

- Step 1: Convert RGB to CMY

Convert tRGB = {R, G, B}. Then convert to CMY: tCMY = {C ', M', Y '} = {(255 - R), (255 - G), (255 - B)}

The choice of the K factor is a relatively complex matter, which is entirely up to the decision of the manufacturer of the printing equipment. K values are kept hidden by manufacturers as a technology secret.

In most cases, the coefficient K will be zero when the saturation of black is lower than 50% to 75% because it is thought that below the reasonable level (completely subjective), it is not necessary to print by black ink.

Theoretically people accept K = min {C '/ 2.55, M' / 2.55, Y '/ 2.55}. (0 <= K <= 100)

The choice of the K factor is a relatively complex matter, which is entirely up to the decision of the manufacturer of the printing equipment. K values are kept hidden by manufacturers as a technology secret.

In most cases, the coefficient K will be zero when the saturation of black is lower than 50% to 75% because it is thought that below the reasonable level (completely subjective), it is not necessary to print by black ink.

Theoretically people accept K = min {C '/ 2.55, M' / 2.55, Y '/ 2.55}. (0 <= K <= 100)

- Step 2: Convert CMY to CMYK

If K = 100 then C = 0, M = 0, Y = 0 (all are black).

If 100> K> 0 then: C = (C '/ 2.55 - K) * 100 / (100 - K), M = (M' / 2.55 - K) * 100 / (100 - K), Y = (Y '/2.55 - K) * 100 / (100 - K) and K = K in which the values C, M, Y, K are rounded to the whole.

This is the ratio of the four colors inks that need to be printed on the same spot to create the required color.

If 100> K> 0 then: C = (C '/ 2.55 - K) * 100 / (100 - K), M = (M' / 2.55 - K) * 100 / (100 - K), Y = (Y '/2.55 - K) * 100 / (100 - K) and K = K in which the values C, M, Y, K are rounded to the whole.

This is the ratio of the four colors inks that need to be printed on the same spot to create the required color.

Correction of colors is necessary because color data can be transferred to the printing device in different formats such as RGB or CMYK. Most of the carton packaging offset printing equipment is now a CMYK support device, so all color data transferred to the printing device must be converted to CMYK format so that they can be used. CMYK color system is also the preferred color system in offset printing technology for carton packaging, labels, namecards and other publications.

Notes when converting RGB to CMYK in offset packaging printing

RGB is the color system used for digital display (computer screen, phone), while offset printing machines use CMYK ink. If the design file is not converted correctly to CMYK, the color may not display correctly when printed.

Therefore, it is necessary to grasp the notes when converting to avoid color errors in the offset packaging printing process:

Therefore, it is necessary to grasp the notes when converting to avoid color errors in the offset packaging printing process:

1. Convert color system from the beginning

When creating a new file, choose CMYK color system instead of RGB to avoid color deviation when exporting the file. With Adobe software, choose CMYK Color Mode right when creating a new document.

2. Avoid using bright or neon colors

Some RGB colors such as bright orange, electric blue, neon pink, etc. cannot be accurately reproduced with CMYK ink. Use the CMYK or equivalent Pantone color chart instead.

3. Check colors with Proof Colors

Turn on View > Proof Colors (in Photoshop/Illustrator) to simulate the color printed on the screen, helping you make early adjustments before exporting the file.

4. Print a test (proof) on real paper before mass production

Don't skip the step of printing 1-2 test copies. This is the surest way to detect color errors and make timely adjustments before printing large quantities of offset packaging.

Understanding and correctly applying color conversion techniques will help your packaging achieve the best print quality, accurately convey your brand message and impress customers.

Offset printed paper packaging Khang Thanh

Close-up of offset printed partial lid wine box sample.

Offset packaging printing ensures clear, sharp and high-quality prints.

Offset printed carton boxes for shoe at Khang Thanh.

Refer to high-quality offset printed carton boxes for pans and household appliances.

Or high-end gift boxes with eye-catching prints to attract customers.

With the outstanding advantages, the technology of offset printing creates high-class finished products with clear images that do not fade over time. Therefore, this is considered as the optimal choice for many industries in the period of fierce integration. The goods are protected with an eye-catching external code, providing sufficient information about products and services. Thanks to these plus points, the supplier will build trust with customers.

Khang Thanh - The packaging manufacturer in Vietnam specializes in producing paper bags, carton box, carton offset, labels, hangtag, books, calendar, POSM and so on.

KHANG THANH - HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com